Steel is a very versatile product and comes in many forms. And speaking of types of steel sheets, corrugated sheets are one of the products that customers purchase the most. This selection of patterned steel sheets has been specifically designed for a variety of applications while offering many of the superior qualities for which steel is highly prized.

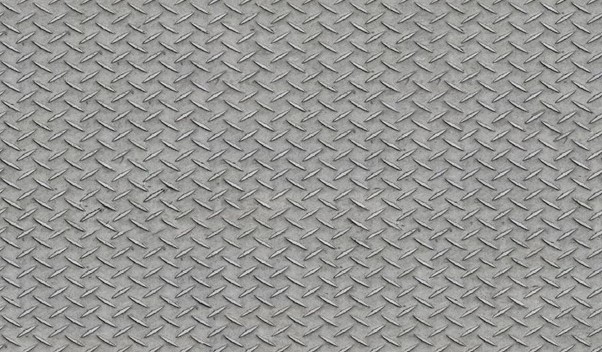

What Is Checkered Steel Plate

A checkered steel plate, or as some may call it, a reticulated steel plate, is a steel plate with a concave pattern on its surface. The pattern on the surface may be a single rhombus, lens, or round bean shape, or two or more patterns may be appropriately combined to form a combination pattern plate. Patterns are mainly used for anti-skid and decoration. A combination pattern board has better anti-slip and bending resistance, uses less metal, and has a better appearance than a single pattern board.

Classifications

First, let’s take a look at the properties offered by corrugated steel:

- Non-Slip – as mentioned, it provides a better grip and a non-slip

- Corrosion and Rust Resistant – inherently resistant to rust and corrosion, it can also be galvanized for extra durability and

- Self-Cleaning – checker plates can be designed with corrugations and holes that allow dirt, grime, water, and other contaminants to drain away, reducing maintenance

- Installing is easy – These panels are lightweight, so you can install them with less effort and for less

- Simple to maintain – Despite the pattern, these panels are extremely easy to clean and Its surface is also resistant to dirt, oil, dust, and liquids.

- Decorative – can be polished or coated to create aesthetic

- Durable – Thanks to its design and natural strength, it can easily withstand heavy traffic and

Benefits

Checkered steel plates can be used for different occasions. It can be useful for construction, docks, and even homes, where checker plate steel used for floors can be a good idea. It depends on how you want to use it. Checker plates are also known as diamond plates or tread plates. The surface has a raised pattern. This pattern isn’t just for aesthetics; it has a specific function and increases traction. Checker plates are useful when non-slip is required. It can be used in industrial warehouses, loading docks, and truck toolboxes. You can use it to add texture to homes with an industrial style. Walking on smooth metal surfaces is usually dangerous. Especially if the surface is wet, it can lead to accidents. Using a checkered plate increases safety as the pattern is designed so that the risk of slipping is minimized. If you want a useful and durable surface that’s non-slip and provides plenty of traction, this material is for you.

Varying Degree Of Uses

Diamond plates are typically used on a variety of safety-related floors and surfaces due to the aforementioned slip-resistant surface. Checker plates are versatile and can be used on industrial sidewalks to create ramps and stairs with a significantly reduced risk of slipping. One example is an outdoor emergency exit. A checkered plate can be used for this purpose to prevent emergency exit steps from becoming slippery in the rain. Another common feature of checker plates is their use on pickup trailers and trucks. Without a good checker plate, your pickup bed can be a den of accidents. The extra traction reduces skidding, especially when loading and unloading material from trucks and trailers. Whether you choose steel or even aluminum checker plates, each can create a unique finish that can appeal to your aesthetic. Many interior architects and designers can see the unique look of checker plates. For home use, these panels can be used for stairs, splashbacks, accent walls, table tops, and other design components.

Cheaper Than Regular Steel Plates

It’s always a good idea to have relatively affordable options when it comes to investing in materials for your project. Going cheap may seem like a good strategy, but the quality you get may not be up to industry standards. Checkered plates offer economic advantages over regular steel plates. Steel plate processing is more expensive than checker plates. To manufacture a standard steel plate, the material must go through a lot of work to achieve the desired thickness. Similarly, checker plates are created in the same way, with one difference. The pattern is embossed directly onto the panel with the last roller. Some steel sheets fresh from the coil are more expensive depending on which supplier you go to. Finding one that is good and can offer quality deals is key. It’s also a good idea to check if the checker plate has a special coating to further improve its durability and anti-slip properties.

Basic Thickness of Checkered Steel Plate

The specifications of the checkered steel plate are expressed by the plate thickness of the base (excluding the plate thickness of the projecting part), and there are 10 specifications ranging from 2.5 to 8 mm. Steel plates No. 1 to 3 are used as templates. The weld on the top of the sample plate should be ground smooth before corrosion protection. In order to prevent weld cracking and arc deformation due to thermal expansion and cold contraction of steel plates, each steel plate joint must have an expansion gap of 2 mm. At the bottom of the steel plate, rain holes with a diameter of 10 mm and a distance of 1 m should be provided. In order to ensure the safety of construction, it is necessary to erect a temporary fence before laying the platform template or install a fence before laying the platform steel plate. The height of the temporary handrail is 1050 mm, and the scaffolding is assembled. A guard bar is placed in the middle. Guardrail surfaces shall be smooth and free of burrs and structural defects.

Precautions

- Materials delivered to the construction site are stacked according to specifications and built-in parts, and the square timbers are padded to prevent erosion due to rain. The stacking height should not be too high to avoid overweight deformation.

- Checker plate laying goes hand in hand with steel structure installation to meet the requirements.

- The steel checker plate requires lifting eyes to be welded to the floor and holes to be welded to the secondary and frame beams must be frame cut.

The greatest use of a checkered steel plate is to reduce slippage on sidewalks, stairs, passages, etc. The added texture ensures extra tracking when moving through materials or walking on this type of surface. It is a great material to use in any condition.

Recent Comments