Hardwood floors are beautiful to look at, but they can be annoying when they start to squeak. Luckily, squeaky hardwood floors do not have to be difficult to fix. There are many ways for homeowners to tackle this annoying problem quickly and easily. With the right home remedies, you can get the creaks and squeaks out of your wood flooring.

As with any DIY, some of the remedies may be temporary, may not work, or may not be carried out to the quality that you would prefer. You could save yourself the hassle and skip right to the professionals. These professional experts can offer a long-lasting, floor-preserving squeak repair.

Below are several ways on how to stop your wood floors from creaking:

Dry lubricant

The squeak in those floorboards may be caused by the two pieces rubbing together as they shift under the weight. You can diminish squeaking sounds by using talcum powder or powdered graphite to lubricate these areas. To do this, select your favoured dry lubricant. Then, sprinkle at the areas where two boards join or wherever the squeaking is occurring.

Cover the area with a cloth or covering and walk over the area multiple times to work the lubricant into the cracks. Some use a two-by-four covered in a cloth instead of just laying the cloth down. Then, they use a mallet to lightly tap the two-by-four on top of the freshly lubricated floorboard. This works too, and either method is acceptable.

Check for missed nails

The squeak may be caused by nails rubbing against joists that were missed during installation. If you can access the subfloor and joists from below, search for such spots. Cut off any nails that are rubbing with bolt cutters. You can have someone help you by walking on the floor above, while you look so that you can locate the exact cause of the squeak.

Insert a finish nail from above

Squeaks can occur because the floor is separating from the subfloor, and the weight applied causes friction. An easy way to get rid of a squeaky floor is to insert a finish nail at the source of the squeak. Ensure to putty up the nail holes after for a seamless finish.

Make sure to insert the nail in the appropriate spot by using a stud finder to locate the joist. This will ensure you aren’t just inserting nails willy-nilly that aren’t going to actually fix the floor. Additionally, if the nail is not inserted into the right spot, it could come loose more easily.

Tackle from below

Measure the location of the squeak so you can locate it from below. Use a couple of screws to secure the subfloor on each side of the joist. Then, use a caulking gun to squirt some wood glue into the gap between the subfloor and the joist. Make sure to use your finger to get it well into the crack.

Next, apply some glue to a two-by-four, and glue it into place in that corner between the subfloor and the joist. Screw the two-by-four into place once you have placed it correctly. Wait for 24 hours before walking on the section again to check if it worked.

Shimming

If you can access the joist and the subfloor, slip a shim in between them. This will eliminate the floor’s ability to shift under weight, which decreases the friction between floorboards when weight is applied.

Use a squeak kit

Available at your local home and hardware store, you could use one of the squeak kits that are available on the market. These are designed to help DIYers like yourself to fix floor squeaks quickly and easily. They are usually cheap, coming in at under $10 a piece. The squeak kit has detailed instructions that ensure you get the job done right.

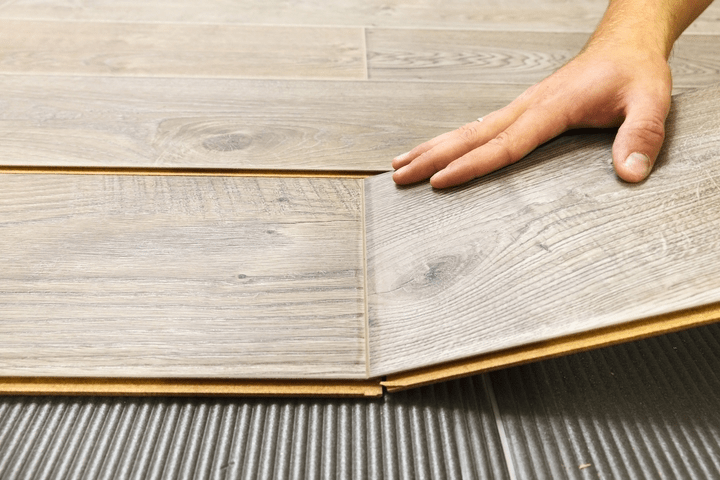

Replace the boards

If none of the easier tricks are working, you may be stuck replacing the boards. You can replace entire boards, or you can replace portions of boards if you think it might be easier.

Use a saw to cut the board into pieces: one cut down each side lengthwise, and one diagonally down the middle. Use a flathead screwdriver to pry the old board out. Then, use a chisel and hammer to pound out the remaining, nailed in piece. Cut the tongue off of the new board and stain it to the appropriate colour if necessary.

When the board is ready, apply some wood glue to the area where it will be placed. Ensure that the board is cut to the correct height for the hole it will be filling. Afterwards, place the new board and use the handle end of a hammer to secure it into place. Insert a finish nail into each end and putty the nail holes for a nice finish.

Recent Comments