Setting up diagonal braces on aluminum mobile scaffolds is critical in ensuring the stability, safety, and efficiency of elevated work platforms. Diagonal braces are vital in maintaining structural integrity by distributing loads evenly and preventing swaying or collapse under pressure.

Whether working on a construction site, performing maintenance, or completing a repair project, understanding the requirements for installing diagonal braces on an Aluminium Mobile Scaffold is essential. This procedure involves adhering to regulatory standards, following manufacturer approaches, and employing best practices for proper assembly. A protected scaffold system improves productivity and minimizes the risk of accidents, safeguarding workers and supplies effectively.

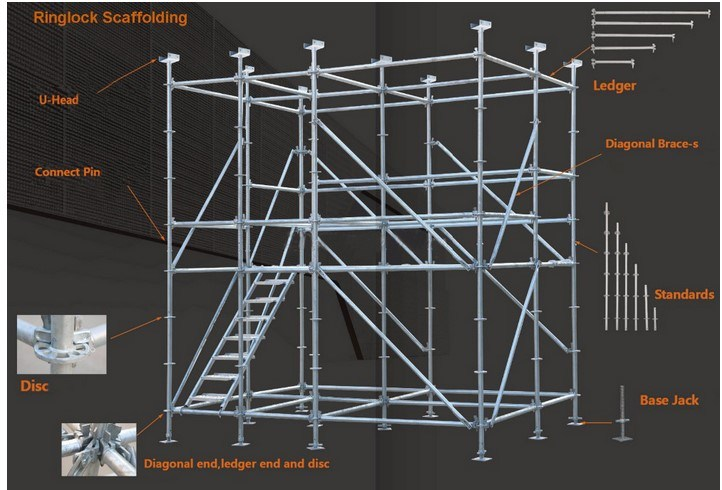

Understanding Diagonal Braces in Mobile Scaffolds

The diagonal braces are the key system of stability in mobile scaffold structures to guarantee the necessary safety and reliability of the elevated working platform. These important components translate the horizontal and vertical parts of the scaffold at an angle thus bearing loads and restraining transverse forces that would otherwise lead to tipping or failure of the scaffold. By preventing movement under pressure, diagonal braces enhance the scaffold’s rigidity, making them indispensable in dynamic work environments. Proper understanding of their placement, installation, and role within the system is crucial for both compliance and safety. Whether assembling a scaffold for construction or maintenance, diagonal braces are key to a robust and reliable structure.

Step-by-Step Guide for Setting Up Diagonal Braces

Diagonal braces are paramount for maintaining the serenity and safety of mobile aluminium scaffolds, preventing swaying and ensuring load distribution. Erasure and catabolism guarantee strict compliance with the safety standards requirements while also defending the workers against possible risks. This article breaks down the procedure into the preparation stage, installation procedure, and final checks to help the user have an efficient and secure process. Even if this is your first time using scaffolds, the use of these steps will assist you in erecting a scaffold that will stand firm.

1. Preparation

Gather Tools and Materials: Ensure all loose pieces such as diagonal braces, locking pins, wrenches, and safety gear are on board as is required.

Inspect the Scaffold: While inspecting one has to be very careful that the scaffold is not in any way damaged or any fitting is missing which will be needed to erect the scaffold.

Level the Ground: It is recommended that the scaffold be placed on a level surface that is strong enough to prevent cases of the structure collapsing over.

Lock the Wheels: Engage the locking systems of the wheels to kneel and lock the scaffold to ensure the scaffold will not move during erection.

2. Installation Process

- Identify the correct attachment points for diagonal braces as per the scaffold design.

- Position the braces diagonally between vertical posts, ensuring alignment at the specified angles.

- Secure braces firmly using appropriate fasteners or locking mechanisms.

- Tighten all connections to eliminate looseness and ensure stability.

- Double-check the placement for uniformity and adherence to guidelines.

- Inspect the overall scaffold structure for rigidity before use.

- Follow manufacturer instructions and safety standards during the process.

3. Verification

- Confirm proper alignment of diagonal braces with vertical and horizontal elements.

- Inspect all connections to ensure they are tight and secure.

- Evaluate the scaffold for stability and the absence of any noticeable sway or movement.

- Perform a load test to verify that braces can support the intended weight.

- Monitor for any deformations or shifting during the load test.

- Ensure compliance with manufacturer specifications and safety regulations.

- Address any discrepancies before using the scaffold.

Materials and Tools Required

Aluminum mobile scaffolds require accurate angling to develop diagonal braces; it is essential to acquire genuine aluminum parts of vertical postages, the horizontal beam, and diagonal braces with guaranteed fasteners and lock systems. For accurate installation include wrenches, screwdrivers, and measuring tapes among other tools. Make sure to use appropriate personal protective equipment every time you are assembling the product.

Structural Requirements

Ensuring structural stability is crucial for aluminum mobile scaffolds. Begin by setting up the scaffold on a firm, level surface to prevent tipping or collapse. Diagonal braces should be placed at precise angles to distribute loads evenly and resist sideways forces. Maintain consistent spacing between braces, and ensure all connections are secure to uphold the scaffold’s rigidity and safety.

Common Mistakes to Avoid

This paper focuses on avoiding improper installation of diagonal braces in aluminum mobile scaffolds to reduce potential risks. One frequent error is improper angle placement, which compromises the scaffold’s structural integrity. Skipping braces on intermediate levels can weaken the entire setup, increasing the risk of collapse. Overlooking wear and tear or failing to inspect components regularly can lead to unnoticed damage that may cause accidents. Another mistake is not following the manufacturer’s specifications, which are designed to ensure proper installation.

Conclusion

Diagonal braces on mobile aluminum scaffolds must be erected correctly to maintain safety, stability, and effectiveness. Following all the regulations, and measures, and using the right materials and instruments you can also guarantee a safe working space to work on.

Maintenance of scaffolds for example through inspection also improves the performance and durability of scaffolds. Considering these requirements not only reduces risks but also is helpful for productivity because workers can easily work through different tasks avoiding disturbing thoughts.

Recent Comments