Confused about whether you need an I-beam or an H-beam? We’ve been there. Steel beams are not exactly exciting to scroll through on TikTok, but they serve as the structural backbone for any strong construction project.

Regardless if you are building a new home, an upscale commercial space, or something completely unique, making the right choice for your project will ensure safety, stability, and satisfaction while keeping your project on budget.

The following guide presents information about the basics without technical jargon, which requires engineering expertise. Are you ready to take this journey? Let’s start!

Why Choosing the Right Steel Beam Matters

Choosing the wrong steel beam is not just a beginner’s mistake. It can interfere with the entire project. Before you find yourself deep into blueprints, budgets, and schedules, consider why it is important to use the right one. That’s where reliable steel beam suppliers step in, providing custom-made steel beams that meet your project’s specifications, schedule, and structural requirements.

Structural Safety Comes First

The correct beam supports your building to remain upright under stress. It loads weight correctly and avoids sagging, bending, or worse—total collapse.

Keeps Costs in Check

Choosing the wrong beam can lead to overspending or needing to redo work, both of which increase your expenses. A good beam offers the right balance of strength and cost without being excessive.

Meets Building Code Requirements

Local codes are not just red tape but exist for safety. The right beam ensures that your project gets through inspection and avoids delay and penalty, or surprise rework. Staying compliant with regulations is also essential in light of broader industry standards and statistics, such as those outlined by the Office for National Statistics on construction.

Boosts Long-Term Performance

A beam that has been appropriately chosen accomplishes two goals: meeting future needs and protecting structures from deterioration and maintenance cost, in short, extending the lifespan of buildings.

Considerable Factors You Must Know Before Choosing

1. Load Type

Determine whether your structure is going to carry a point load, a uniform load, or a combination of both. Each load type affects how the beam responds to stress and distributes the weight.

2. Load Weight

For heavier loads, you need stronger, more durable beams. If you overestimate, you waste money. If you underestimate, there is a possibility of collapse. So, it’s crucial to have accurate calculations.

3. Span Length

The more widely spaced the supports are, the heavier and deeper the beam will have to be. All about spanning safely.

4. Support Placement

Beams are used alongside columns or walls. The location of the supports matters because it affects how much weight the beam can support and how large it should be.

5. Beam Depth

Length also becomes an important aspect in terms of a beam’s resistance to bending. Longer beams tend to support more weight but may have an effect on headroom or design space.

6. Flexibility vs. Rigidity

Some projects require beams that flex slightly under pressure, while others require stiff beams that will not move. The type of use dictates what will work best.

7. Beam Orientation

All the details about the beam’s position on the vertical, horizontal, or sloped side will determine how it will react to a force. Orientation determines strength, and so does the selection of proper size and shape.

8. Environmental Conditions

Corrosion comes into play when beams have a moisture effect, as in the coastal type of climate, or when there are changing temperatures. To prevent corrosion effects, the use of beams having anti-corrosive paint or coatings would be useful, while the use of corrosion-resistant material would be another option.

9. Fire Resistance

Steel must usually comply with fire safety codes for commercial and industrial applications. Depending on the beam type, a fire-rated coating or insulation may be required.

10. Connection Type

How the beam connections are made, welded, bolted, or slotted will affect the speed of installation, the stability of the project overall, and options to readjust or upgrade in the future.

For welded connections, it’s critical to use the proper welding tools, including protective gear like helmets and specialized welding lenses, to ensure both precision and safety on the job site.

Common Types of Steel Beams and Their Uses

I-Beam (W-Beam)

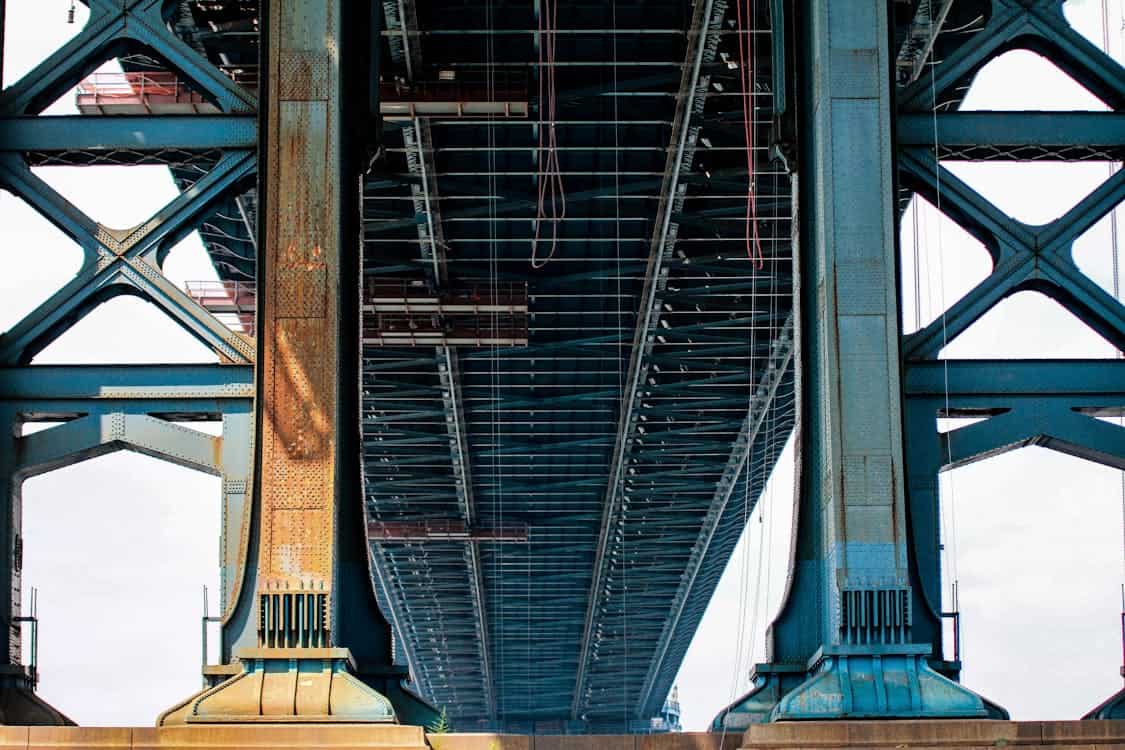

The classic beam has a tall center web and slender flanges, making it ideal to support heavy vertical loads from bridges, buildings, and spans with a small material waste.

H-Beam

Wider and thicker than an I-beam, the H-beam can take both horizontal and vertical loads in its stride. Ideal for large commercial and industrial constructions.

C-Channel Beam

This beam is shaped like a squared-off “C.” It is an ideal selection for lighter structural framing, bracing, or short spans. It is easy to fabricate and install.

T-Beam

A T-beam provides additional strength at the intersection of concrete slabs and steel reinforcement. Ideal for floors and bridges where you have a need for strong tension support at the bottom.

Box Beam

Due to their encapsulated rectangular or square design, box beams supply outstanding torsional strength capabilities. The steel beams prove most useful for platforms and crane systems as well as demanding industrial structures.

Conclusion

Selecting a steel beam is more than strength, it encompasses safety, savings, and long-term success. A wise choice will guarantee the structure’s strength, prolonged life, and sound performance.